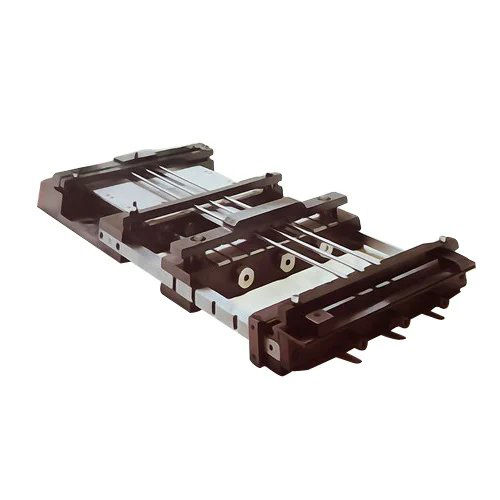

Pneumatic Roll Band Feeder

59700 INR/Piece

Product Details:

- Product Type Pneumatic Roll Band Feeder

- Operating Type Automatic

- Pressure 6 Bar

- Surface Treatment Coated

- Color Black-Yellow

- Warranty 1 Year

- Usage & Applications Industrial

- Click to view more

X

Pneumatic Roll Band Feeder Price And Quantity

- 1 Piece

- 59700 INR/Piece

Pneumatic Roll Band Feeder Product Specifications

- 6 Bar

- Black-Yellow

- Automatic

- Pneumatic Roll Band Feeder

- Coated

- 1 Year

- Industrial

Pneumatic Roll Band Feeder Trade Information

- Cash Advance (CA)

- 10 Piece Per Month

- 10 Days

- All India

Product Description

A Pneumatic Roll Band Feeder is a specialized piece of equipment used in metal stamping and coil processing industries. It is designed to handle various types of metal coils or strips, such as steel, aluminum, or other alloys. This feeder is designed to precisely feed metal strips or coils into stamping presses or other processing machinery. The feeder is equipped to handle specific ranges of coil or strip widths and thicknesses, offering versatility for different materials. Pneumatic Roll Band Feeder contributes to the efficiency and precision of metal stamping and forming operations by providing controlled and accurate feeding of metal strips into stamping presses or other machinery.

FAQs of Pneumatic Roll Band Feeder:

Q: What is the warranty period for the Pneumatic Roll Band Feeder?

A: Yes, the product comes with a warranty.Q: What is the operating type of the Pneumatic Roll Band Feeder?

A: The operating type of the Pneumatic Roll Band Feeder is automatic.Q: What is the surface treatment of the Pneumatic Roll Band Feeder?

A: The surface treatment of the Pneumatic Roll Band Feeder is coated.Q: What is the pressure requirement for the Pneumatic Roll Band Feeder?

A: The Pneumatic Roll Band Feeder requires a pressure of 6 Bar.Q: What is the usage and application of the Pneumatic Roll Band Feeder?

A: The Pneumatic Roll Band Feeder is suitable for industrial usage and applications.Q: What is the color of the Pneumatic Roll Band Feeder?

A: The Pneumatic Roll Band Feeder comes in a Black-Yellow color.Q: Is the Pneumatic Roll Band Feeder suitable for heavy-duty applications?

A: Yes, the Pneumatic Roll Band Feeder is designed for heavy-duty industrial applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free