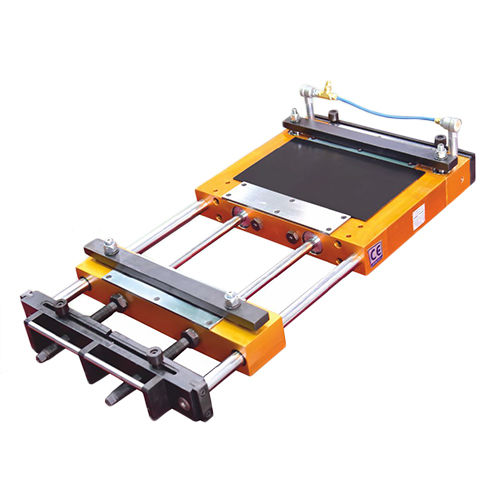

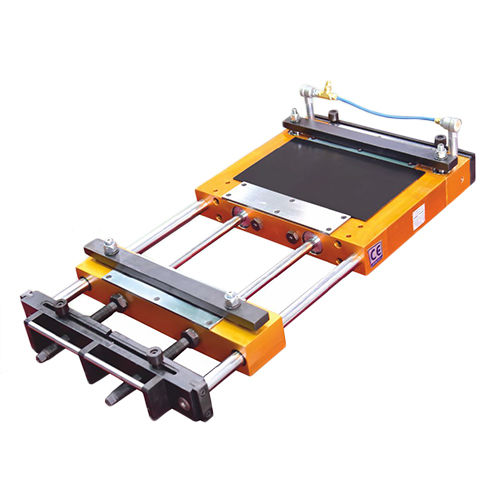

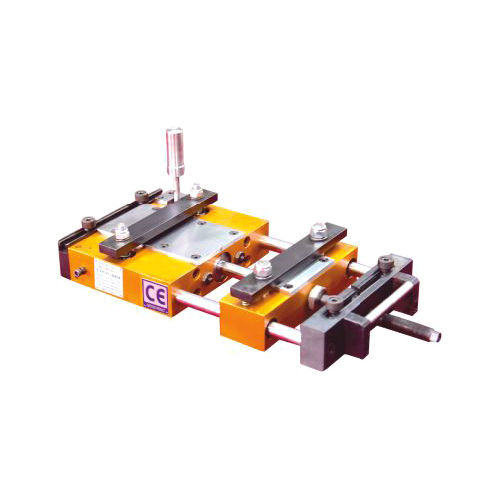

High Precision Pneumatic Feeder

60500 INR/Piece

Product Details:

- Structure Standard

- Usage Industrial

- Material Steel

- Size Standard

- Product Type Dual Cylinder Pneumatic Feeder

- Color Yellow-Silver

- Click to view more

X

High Precision Pneumatic Feeder Price And Quantity

- 60500 INR/Piece

- 1 Piece

High Precision Pneumatic Feeder Product Specifications

- Dual Cylinder Pneumatic Feeder

- Industrial

- Standard

- Steel

- Standard

- Yellow-Silver

High Precision Pneumatic Feeder Trade Information

- Cash Advance (CA)

- 10 Piece Per Month

- 10 Days

- All India

Product Description

A Dual Cylinder Pneumatic Feeder is a type of feeding mechanism commonly used in various manufacturing processes, particularly in metal stamping and forming applications. The dual-cylinder configuration is often chosen for its ability to provide more precise control and stability during the feeding process. This feeder is designed to advance and position metal sheets or strips in a controlled manner within a press or other production equipment. They are designed for relatively quick setup and changeovers between different stamping and forming jobs. Dual Cylinder Pneumatic Feeder s is chosen for their simplicity, cost-effectiveness, and suitability for specific applications where pneumatic operation meets the production requirements.FAQs of High Precision Pneumatic Feeder:

Q: What material is the High Precision Pneumatic Feeder made of?

A: The High Precision Pneumatic Feeder is made of steel.Q: What is the size specification for the High Precision Pneumatic Feeder?

A: The High Precision Pneumatic Feeder is available in a standard size.Q: What is the color of the High Precision Pneumatic Feeder?

A: The High Precision Pneumatic Feeder comes in a Yellow-Silver color combination.Q: What is the usage of the High Precision Pneumatic Feeder?

A: The High Precision Pneumatic Feeder is designed for industrial use.Q: What is the structural design of the High Precision Pneumatic Feeder?

A: The High Precision Pneumatic Feeder features a standard structure.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free